Where Innovation

Meets the Board: Smarter PCB Design Starts Here

ADVANCED MANUFACTURING TECHNOLOGIES

FULL TURNKEY ELECTRONIC MANUFACTURING

SINCE 1990

The Leader in Printed Circuit Board Design, Engineering, Assembly & Testing

Advanced Manufacturing Technologies (AMT) is a world class, full-service electronic contract manufacturer of next-generation printed circuit board (PCB) and electro-mechanical assemblies. AMT far surpasses the industry norm, demonstrating unparalleled customer service and state of the art processes and equipment.

ENGINEERING

In-House, Full-Service Engineering

Whether your application is in aerospace, automation, defense, industrial, medical, power, process control, or consumer electronics, we offer a range of engineering services, including:

- Conceptual Design

- Schematic and PCB Layout Design

- Electromechanical Design

- Embedded Design Development

- Design for Test (DFT)

- Design for Manufacturing (DFM)

- Updating Existing Platforms for Obsolescence or Enhanced Features

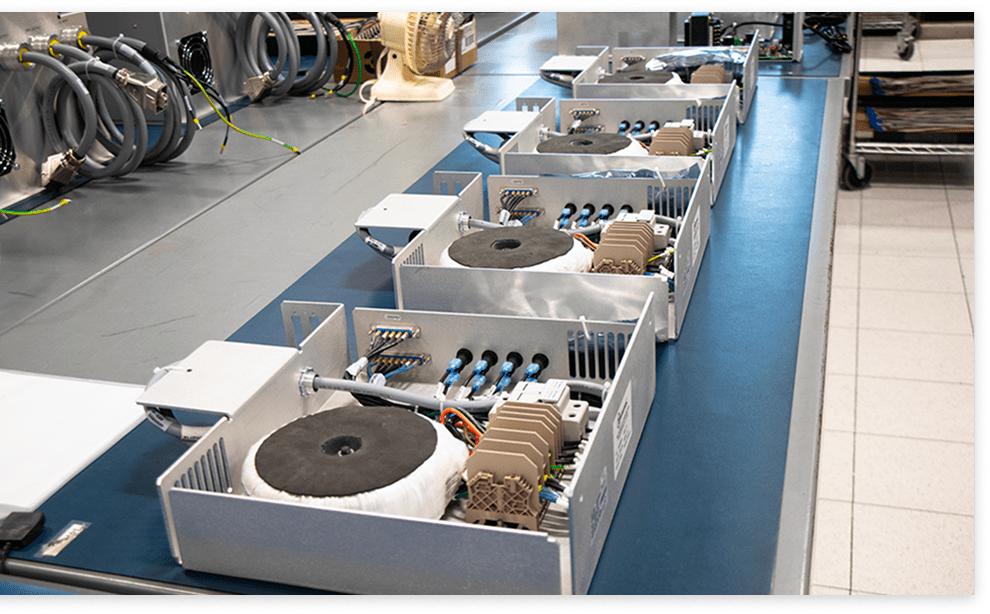

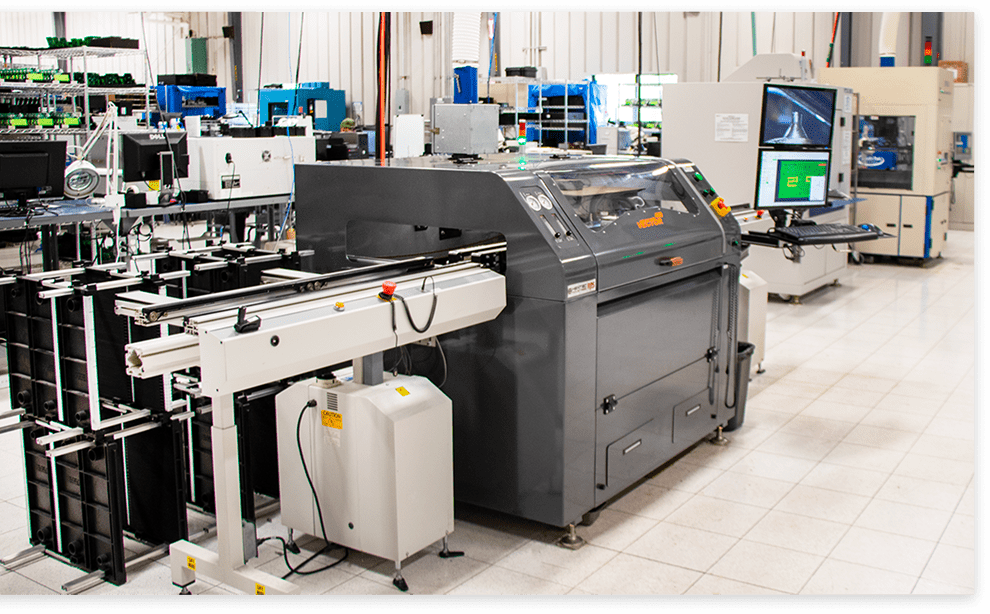

ASSEMBLY

AMT offers Through Hole, Surface Mount (SMT) and Mixed Technology PCB assembly.

- Through-Hole

- Surface Mount (SMT)

- Mixed Technology

- 3D Optical In-Line Inspection

- Electromechanical

- Chassis Assembly

- Box Builds

We also perform In-Line Selective Soldering and Axial Lead Insertion Automation.

Our company’s approach to manufacturing printed circuit boards (PCBs) and electro-mechanical assemblies includes Surface Mount Technology (SMT), Through-Hole Technology (THT) and Mixed Technology to accommodate various component types and applications and employs advanced equipment and processes in compliance with IPC standards.

TESTING

At AMT, our engineers offer technical consultations and test your PCBs to ensure they’re field-ready.

- Functional

- In-Circuit

- Final Systems

- Flying Probe

SPECIAL PROCESSES

Our unique processes surpass the standard capabilities of a typical electronic contract manufacturer.

- Selective Solder

- RoHS-Compliant Manufacturing

- Conformal Coating

- Prototyping

- Semi-Automated Rework and Repair

- X-ray Inspection

- Laser Bar Coding

Our Customers Represent a Wide Range of Industries

Aerospace

Automation

Robotics

Medical

Defense

Power

Process

Control

Motion

Control

Consumer Products

Testimonials

At DynaVox, we depend on our key suppliers to keep us informed on upstream supply chain issues, product manufacturability and testability, potential quality concerns, and component obsolescence. Most importantly, we need suppliers that take a proactive position in keeping us in supply of quality product at the lowest total acquisition cost. AMT has demonstrated stellar performance in achieving these objectives. The results that AMT has repeatedly demonstrated gave us the confidence to direct a greater share of our contract manufacturing needs to them, knowing that they will deliver on expectations.

Tony Pavlik

Vice President, Operations

DynaVox Technologies

Pittsburgh, PA

AMT is a valuable asset located here in our own backyard. They consistently meet or exceed our expectations, whether we are dealing with PCBs or complete electro-mechanical assemblies. AMT is a true partner in the sense that they help us with our own internal processes and documentation to improve our ability to manage our build-to-print procurements.

Frank Davis

Manufacturing Manager

ACUTRONIC USA

Pittsburgh, PA